Our Services

- Home

- Our Services

STRUCTURAL ASSESSMENT

RETROFITTING MANAGEMENT

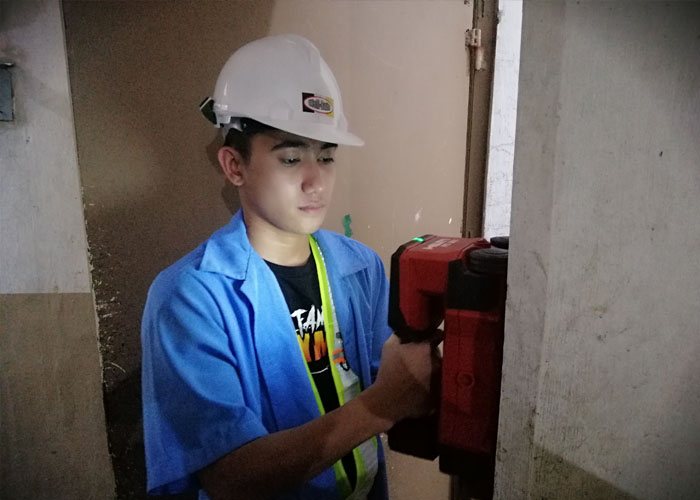

To achieve a successful repair/retrofit project, a thorough investigation of the structure involved is imperative. Existing structural condition shall be recorded and analyzed. Structural assessment shall be done with physical tests and computer modeling.

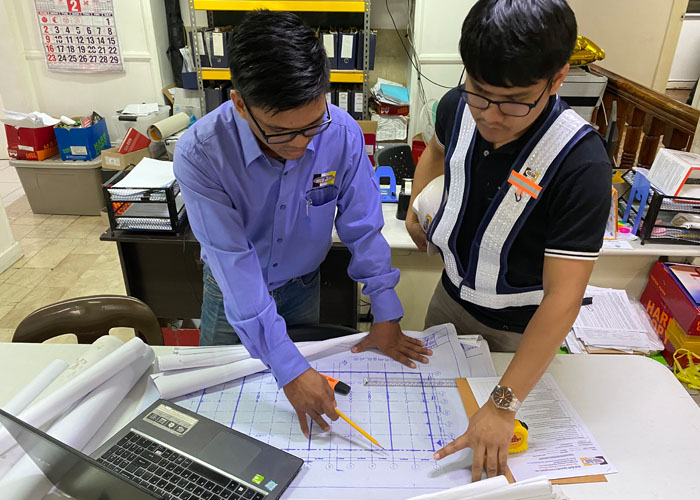

Retrofitting projects shall follow a planned schedule to avoid delays and add-on costs. Contingencies shall as well be considered as repair projects have plenty of unforeseen scenarios. An experienced contractor can lessen such unforeseen problems.

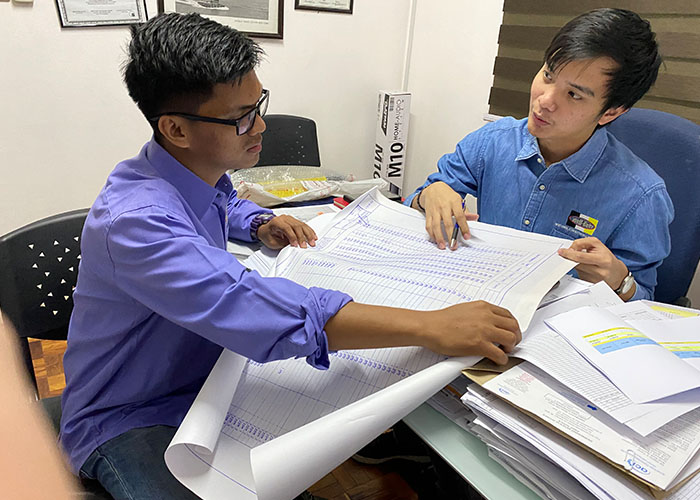

Investigation reports and analysis shall be the basis of appropriate retrofit/enhancement application. Methodologies shall conform to site conditions and applicability of the selected method.

Safety in the construction industry is number one consideration. It is everybody’s concern and responsibility. Standard safety regulations shall be followed plus special safety precaution in the application of specialty chemicals. Material Safety Data Sheet shall be available prior to use of these materials.

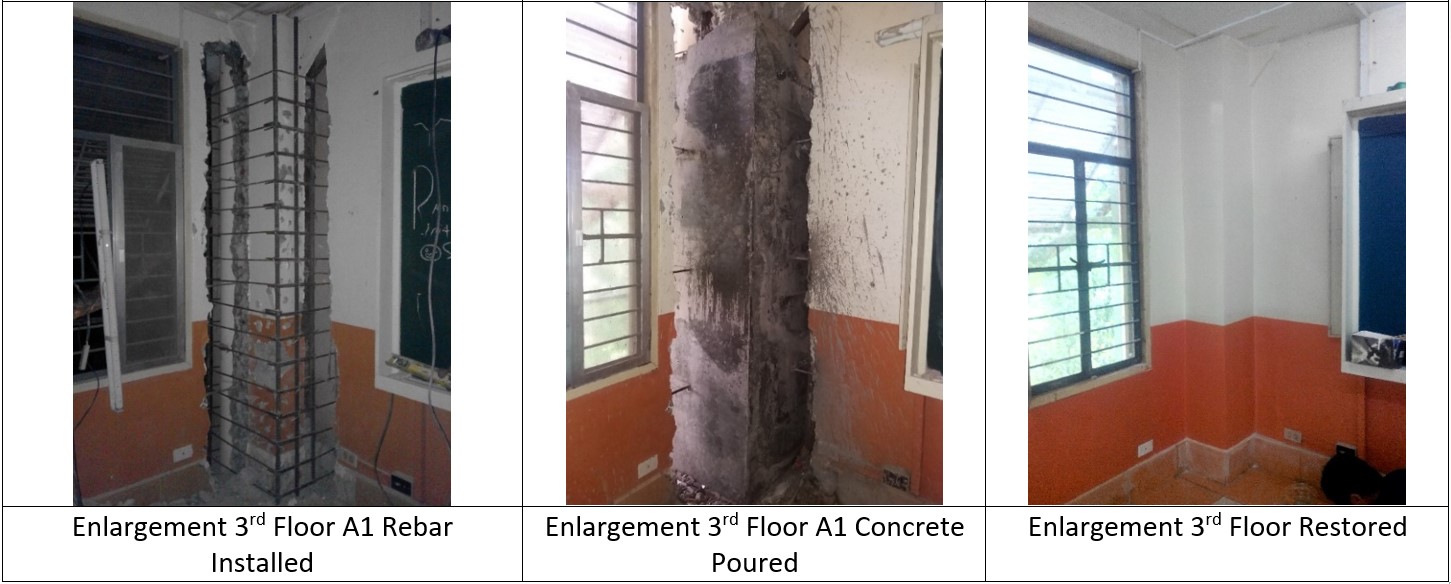

RETROFITTING CONSTRUCTION AND DESIGN

Advantages:

CONCRETE REPAIR / RESTORATION

These defects can be rectified by several methods – hand patch, chip and patch, form and pour and by shotcrete. Again, each method has its own advantage for every type of repair. The engineer always be responsible for the best method.

Grouting works involves non-shrink cementitious & polymer materials. Different grout applications are in heavy machinery foundation, high vibration motor foundation, column base plates.

Cracks in concrete are normal as concrete is weak in tension. Some cracks may not need repairs but most cracks must be rectified, depending on its effect on the structure. There are several methods of crack repairs such as routing & sealing, gravity method, high & low pressure injection. The engineer shall select the most appropriate method to achieve a successful and economical project.

VALUE ENGINEERING

With the Collaboration of our Site Engineers, Structural Engineers and Quantity Surveyor Engineers; re-evaluation for other methodology, material and design possible based from the applied restrictions and conditions of the client shall be calculated to aim an economical cost for the project.

Other Services

- Sealant Application

- Industrial Floor Coating

- Seismic Joint System